Quality Control

We believe that the quality of our products are also our best marketing tool Quality is the nucleus of all our activities , quality & endurance of our products are the prime motivating factore

Quality Commitment

At JK Industries, our commitment to quality is the cornerstone of our operations. We are dedicated to delivering precision, reliability, and excellence in every aspect of our custom precision turned and milled parts manufacturing.

Traceability and Documentation

Detailed documentation and traceability records are maintained for every stage of production, ensuring transparency, accountability, and the ability to address any concerns that may arise.

Continuous Improvement

We actively engage in continuous improvement initiatives. Analyzing any deviations, implementing corrective actions, and integrating client feedback contribute to enhancing our manufacturing processes.

Customer-Centric Approach

Understanding and meeting our clients' specific requirements are central to our quality commitment. We work closely with clients to ensure that their expectations are not only met but exceeded.

Ethical and Sustainable Practices

Our commitment to quality extends to ethical and sustainable manufacturing practices. We prioritize environmental responsibility, waste reduction, and safe working conditions.

Rigorous Quality Control

Quality control is embedded at every stage of production, from material inspection to final assembly. Our comprehensive inspection protocols and testing methodologies ensure that each component leaving our facility adheres to the highest quality standards.

ISO Certification

JK Industries maintains ISO 9001: 2015certification, underscoring our commitment to following internationally recognized quality management systems. This certification validates our dedication to delivering consistent quality.

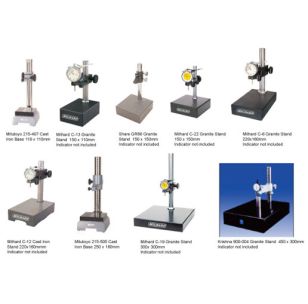

Inspection Technologies

We utilize state-of-the-art inspection technologies, including coordinate measuring machines (CMMs), optical comparators, and other advanced tools to verify the accuracy and integrity of our components.

Precision Manufacturing

We operate with advanced CNC machinery and cutting-edge technology, ensuring that every component we produce meets the strictest dimensional accuracy and tight tolerances required by our clients.

Skilled Workforce

Our team comprises experienced engineers, machinists, and quality control specialists who bring their expertise to every stage of the manufacturing process. Their dedication and skills are essential in maintaining our high-quality standards.

Material Selection

We carefully select materials grade that align with customer requirements and performance expectations of each component. Our materials expertise ensures that the right material grade isused to meet the requirements of our clients.

Reliability and Consistency

Our reputation as a reliable partner is built on consistent quality. Clients can rely on us to deliver components that consistently meet their specifications and perform reliably.

Continuous Training

Our team undergoes regular training to stay updated with the latest industry advancements, technologies, and quality control methodologies.

We are used to meeting the highest standards as follows.

- ISIR with cover sheet, PPAP Level 1-5, VDA 1-3,

- Control Plan, PFMEA, SPC, MSA Study as per AIAG

- Optical measurement for quality assurance of the series parts with documentation.

- Documented and traceable exit control.

- Ongoing control of the material during production using letest technology.

- Precise labeling of the parts or barcode printing.